Main benefits

Product environment

Sécheron possesses decades of experience designing and manufacturing high-voltage DC electrical safety components for the traction circuits powering DC rail vehicles of all kinds.

Our UR series DC circuit breakers are available in a broad range of configurations and with optional features to meet the needs of metro vehicles, Light Rail Vehicles (LRV), tramways, EMUs, DC trains (including high-speed DC trains) and DC locomotives. Our products can be delivered as stand-alone components you can integrate into your own line breaker boxes and converters. For car builders seeking high performance, reduced engineering work and easier vehicle manufacturing combined with lower maintenance, we can also provide turnkey solutions, integrating our DC circuit breakers into our smart, compact MODBOX®-type high-voltage enclosures with other high- and low-voltage electrical safety, measurement, and traction chain control components.

Power converter manufacturers, car builders, traction propulsion equipment manufacturers, and DC rail operators have come to rely on our experts for personalized support throughout all phases of their projects, from recommending the most appropriate solution to obtaining local after-sales service worldwide throughout the lifetime of their products.

Product description

- Bi-directional and with trip free direct acting device.

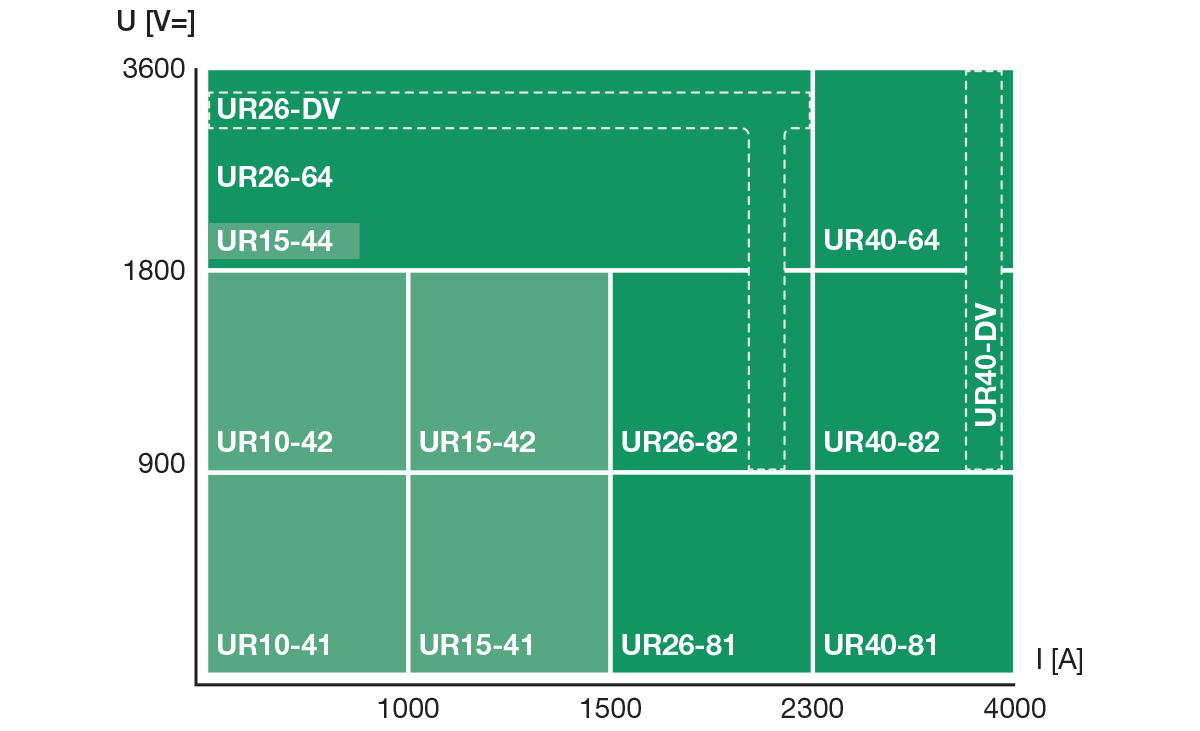

- Rated Voltage 900 Volts, 1800 Volts, 3600 Volts.

- Also available for dual voltage 1800 Volts / 3600 Volts.

- Current range from 1000 A to 4000 A.

- Making & breaking capacity matching operational needs.

- Electromagnetic closing.

- Control voltage from 24 to 110 VDC.

- Auxiliary contacts for main contact position indication.

- Operational frequency C3 - Heavy Duty.

- Constant & limited arc voltage during current interruption.

- Optional protective enclosure (IP55) for direct roof or under-frame installation.

- Ambient temperature - 25 °C to +70 °C (-50 °C to +55 °C in option).

- Reference standards: IEC 60077-3.

- Insulation material according to EN 45545-2.

Useful links